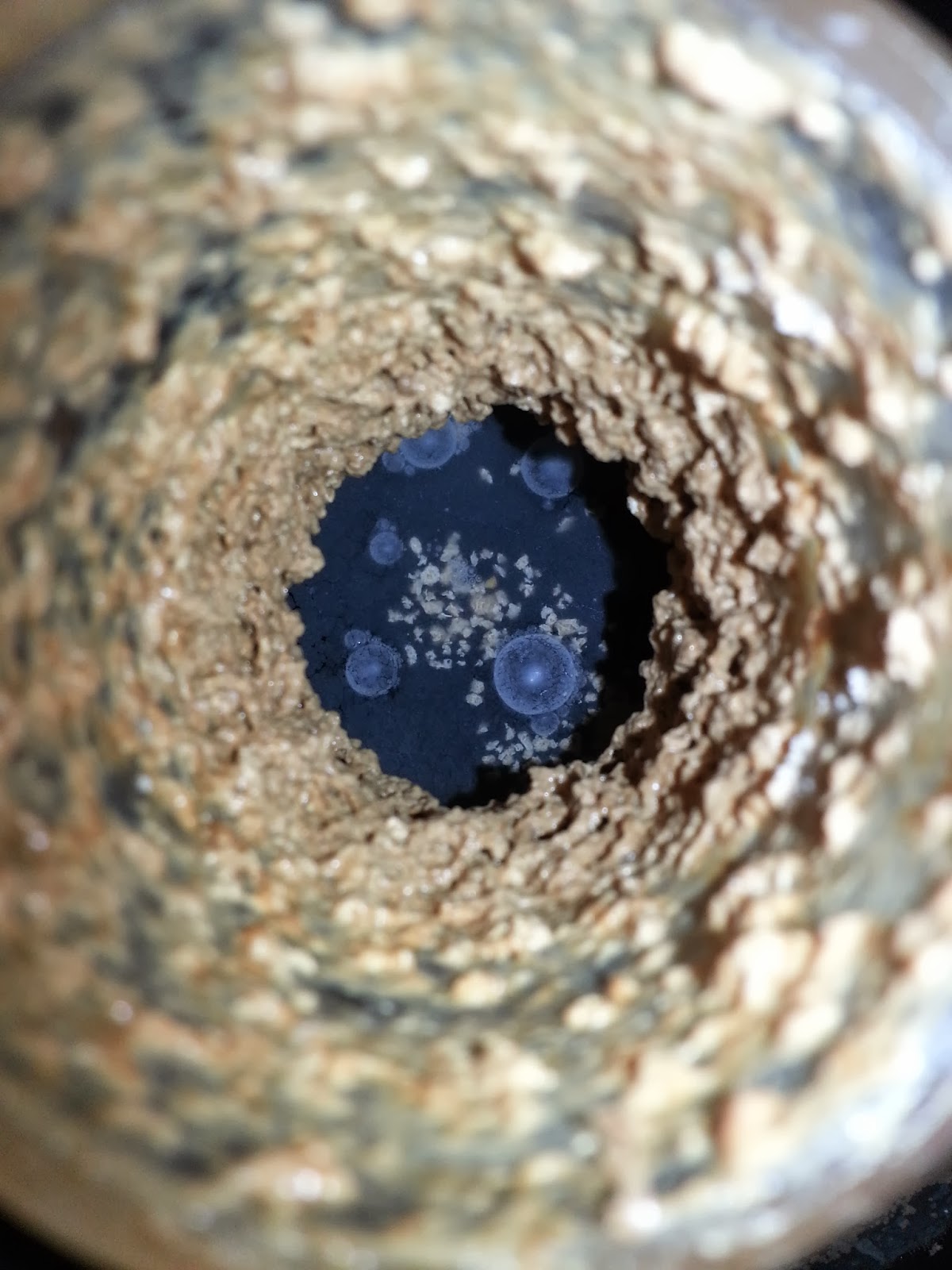

Lambic Solera Update #18 -- Two month into year four (or thirty-eight months into the solera)

Adam Kielich

February 18, 2014

1 Comments

I have fallen behind on updating the lambic solera after I brewed the fourth batch going into the fermentor in December 2013 but I am going ...

Read More